OEM China Long Steel Wedge - Steel wedge – Bocheng

OEM China Long Steel Wedge - Steel wedge – Bocheng Detail:

Steel wedge is mainly used in the initial construction period of power plants to adjust the parallelism of steel beams or to install and adjust mechanical equipment and machine tools. Steel oblique iron is mainly used for the installation and adjustment of steel structure, as well as the installation and adjustment of equipment; the characteristics are: smooth surface, high precision, no burrs around, good toughness, and easy to use

Technical requirements for Steel wedge: the accuracy is determined according to needs, because wedge generally uses upper and lower sides, so the requirements for the four sides are generally not high, and the roughness of the steel wedge is 6.4 ; The roughness of the upper and lower surfaces of the wedge is 12.5, 6.4, 3.2, 0.8, etc., if the accuracy is higher, the flatness and parallelism of the steel wedge processed by the grinder may not exceed 0.03mm. The thickness of the steel wedge can be determined according to actual needs and the material and specifications of the material; the slope of the steel wedge should be 1/10-1/20, the steel wedge of vibration or precision equipment The slope of the shim) can be 1/40. When using steel wedge, it should be used in conjunction with the flat shim of the same specification. The steel wedge should be used in pairs. The same slope should be used.

The drawings of the steel wedge are designed according to the actual equipment base requirements, and then processed according to the drawings.

How to use the steel wedge

Place a flat shim on the concrete foundation, and then place the two steel wedge on the flat shim. When adjusting, use a hammer to hit two steel wedges, the slope of the steel wedge is used to raise or lower the equipment to achieve the purpose of adjusting the level. After the level is adjusted, spot weld the steel wedge with the base of the equipment to make the shim firm and firm. Finally, it is poured with concrete to keep the equipment in a good level during operation, reduce machine wear and tear, and reduce the cost of replacing equipment parts.

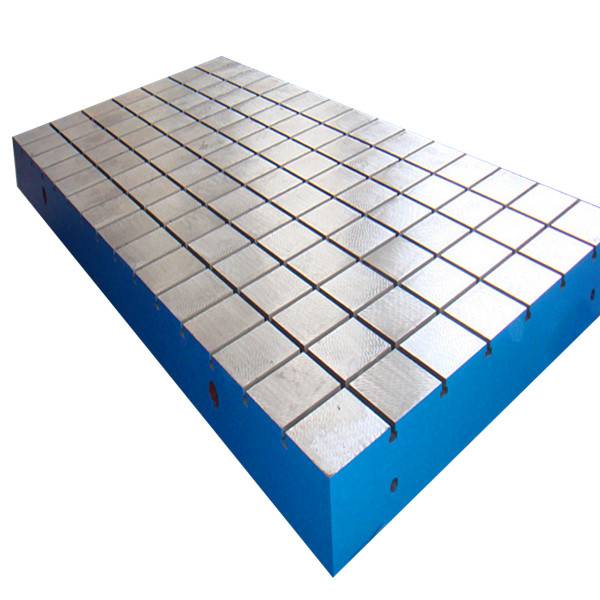

Product detail pictures:

Related Product Guide:

Our primary objective is usually to offer our shoppers a serious and responsible small business relationship, offering personalized attention to all of them for OEM China Long Steel Wedge - Steel wedge – Bocheng, The product will supply to all over the world, such as: Mexico, Finland, Philadelphia, All the imported machines effectively control and guarantee the machining precision for the products. Besides, we have a group of high-quality management personnels and professionals, who make the high-quality products and have the ability to develop new products to expand our market home and abroad. We sincerely expect customers come for a blooming business for both of us.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.