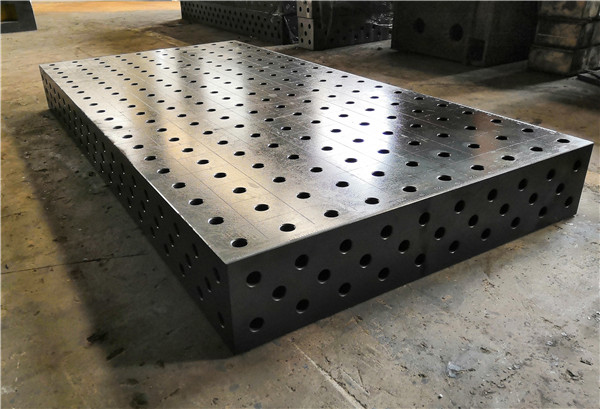

Nitiriding steel 3D welding table

Nitiriding steel 3D welding table,

3d Welding Table,

Welding tables After Nitriding treatment will be with High hardness, no rust, prevent welding slag sticking to the table surface

Tables of the following sizes are in stock

D 28 3D welding table

|

4000x2000x200mm |

3000x2000x200mm |

|

3000x1500x200mm |

2000x1500x200mm |

|

2400x1200x200mm |

2000x1000x200mm |

|

1500x1000x200mm |

1200x1000x200mm |

|

1000x1000x200mm |

5000x2000x200mm |

|

4000x2500x200mm |

3000x2500x200mm |

|

4000x1500x200mm |

4000x1000x200mm |

|

2500x1500x200mm |

3000x1000x200mm |

|

2500x1000x200mm |

2000x2000x200mm |

|

1500x1500x200mm |

1200x1200x200mm |

D22 3D welding table

|

2000x1500x200mm |

2000x1000x200mm |

|

2400x1200x200mm |

1500x1000x200mm |

|

1200x1000x200mm |

1000x1000x200mm |

D16 3D welding table

|

2000x1500x150mm |

2000x1000x150mm |

|

2400x1200x150mm |

1500x1000x150mm |

|

1200x1000x150mm |

1000x1000x150mm |

2D welding table

|

2000x1500mm |

2000x1000mm |

|

2400x1200mm |

1500x1000mm |

|

1200x1000mm |

1000x1000mm |

|

1200x800mm |

1200x1200mm |

We can customize tables of different sizes according to your requirements

3D Welding table: five working surfaces the locating piece can be installed on. Also can be extended via any of its five working surfaces.

• For its material divided into: Steel Welding Tables and Cast iron Welding Tables

• For its hole diameter divided into: D28 series ,D22 series and D16 series.

Diagonal Grid: D28 and D22 is 100*100mm; D16 is 50*50mm

Supporting: legs, steel frame according to the requirement.

Components can be equipped after your selecting:

1, Tools for supporting: U-Shaped cube case, L-shaped cube case, Angle supporting, and Angle gauge

2, spare parts for Locating:

3, Tools for clamping and fixing

4, spare parts for locking working piece

5, Auxiliary Tools

Features

• Almost all workpiece can be fixed precisely at certain points or surfaces with locating piece, adapting piece, fastening piece and supporting piece, in the process of assembling or welding.

• Imprecise dimensions of workpiece can be adjusted during preliminary working process.

• It is easy to use existing parts in the workshop to imitate workpiece assembly via CAD.

Economical

• Save much cost instead of reserving a lot of complicated and expensive traditional fixtures

• Applies to various working conditions without the need of any modification

• Easy and safe to operate.

Flexible

• Solid enough to bear extremely heavy loads.

• Five surfaces, regular holes and grid lines(no inclined holes or T-shaped grooves)

• Any workpiece can be fixed and clamped on the table with locating pins

• 3D welding tables can link together against any of its five surfaces.

Precise

• Almost all workpiece can be fixed precisely at certain points or surfaces with locating piece, adapting piece, fastening piece and supporting piece, in the process of assembling or welding

• Imprecise dimensions of workpiece can be adjusted during preliminary working process.High-performance 3D welding table system

The welding fixture can be arbitrarily matched according to the requirements of different products to ensure the welding quality and greatly save working time.